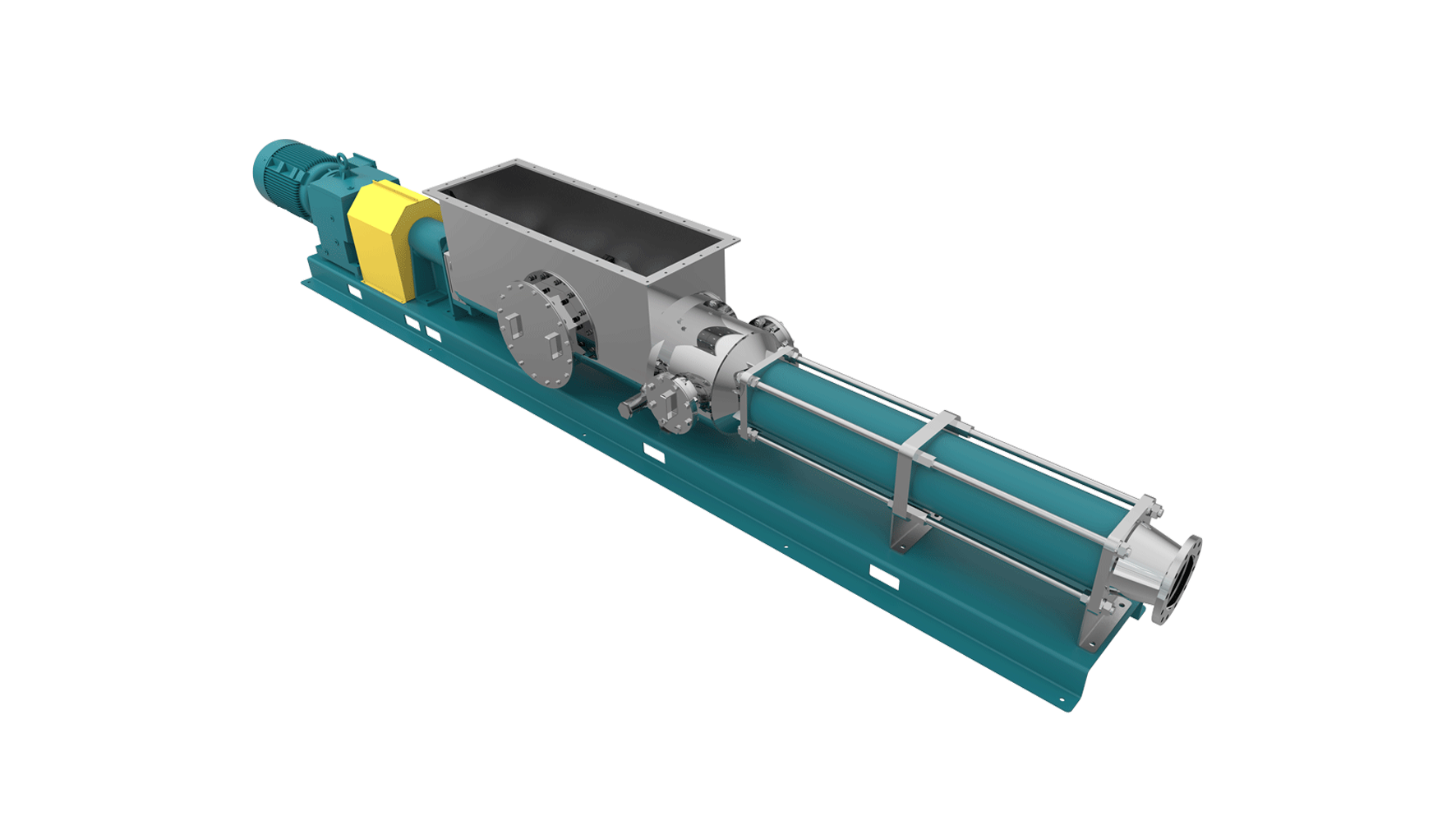

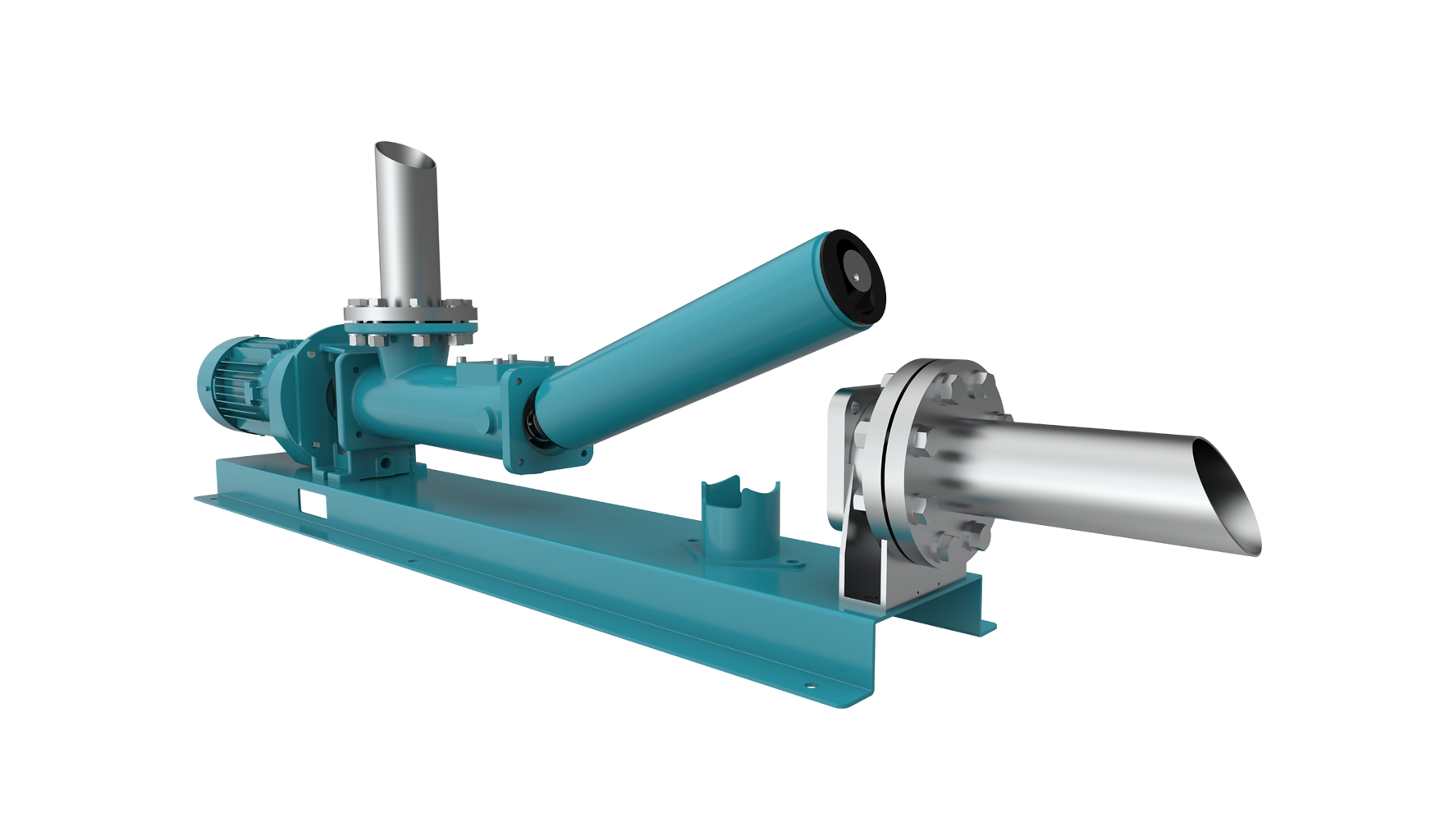

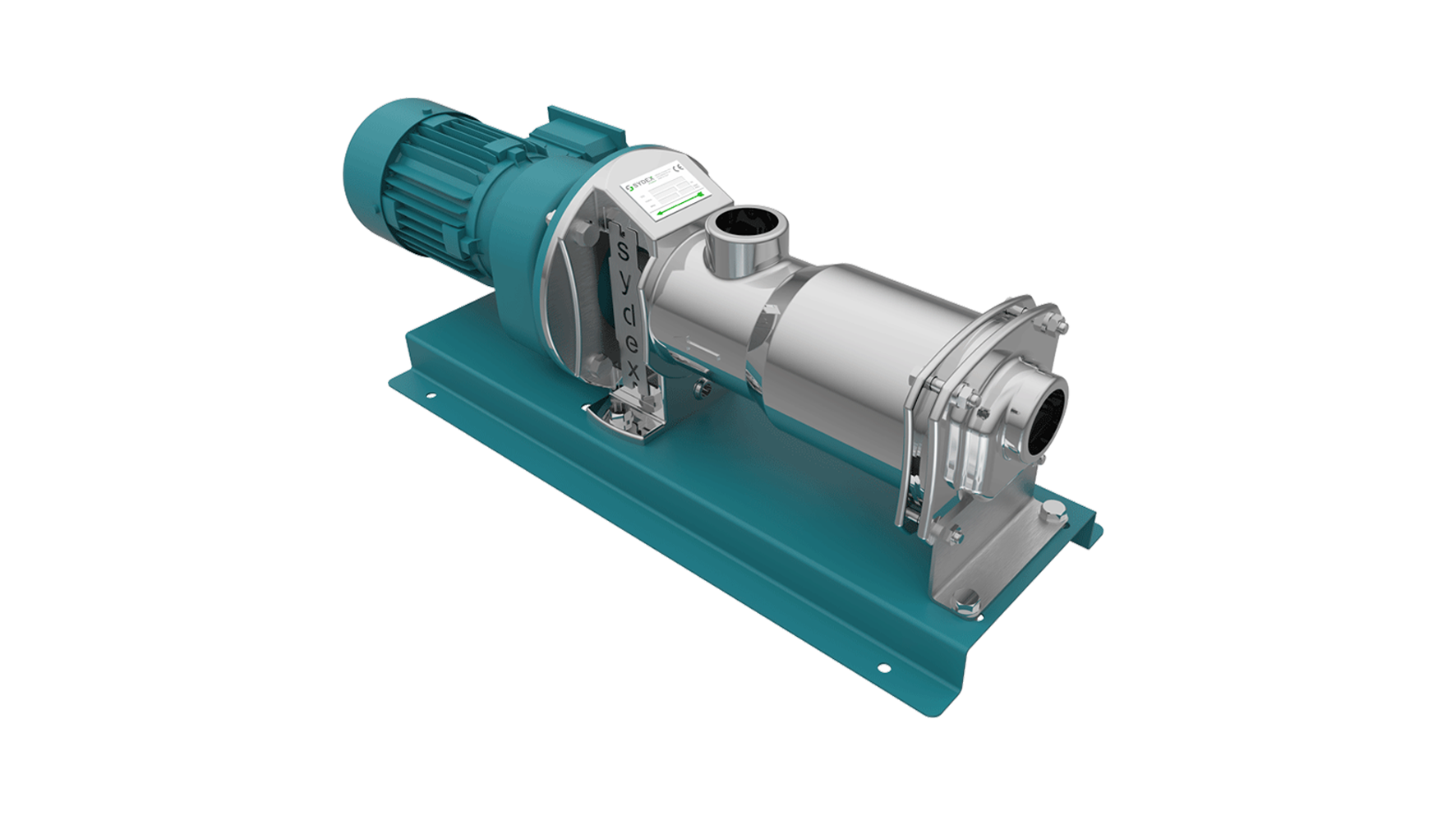

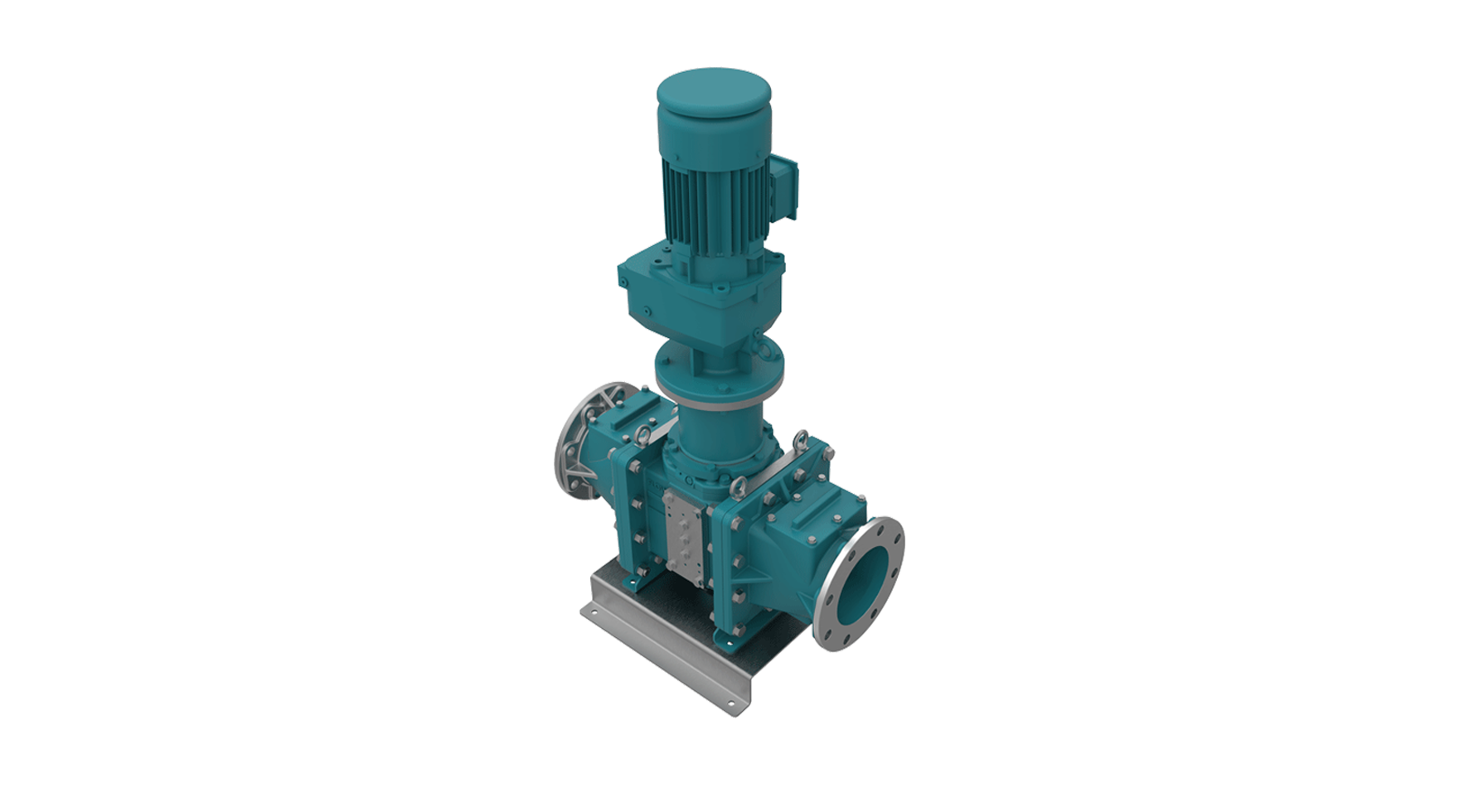

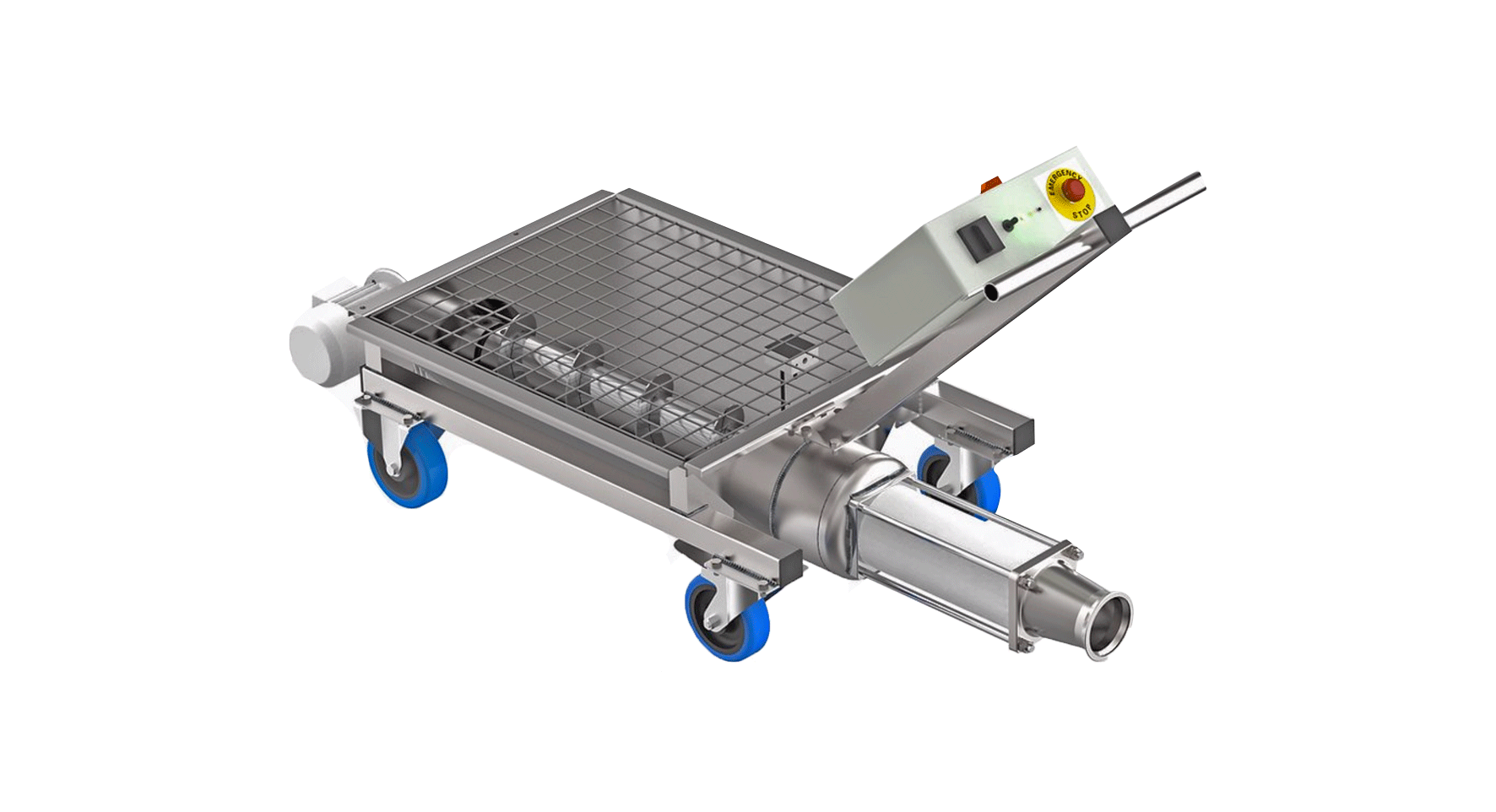

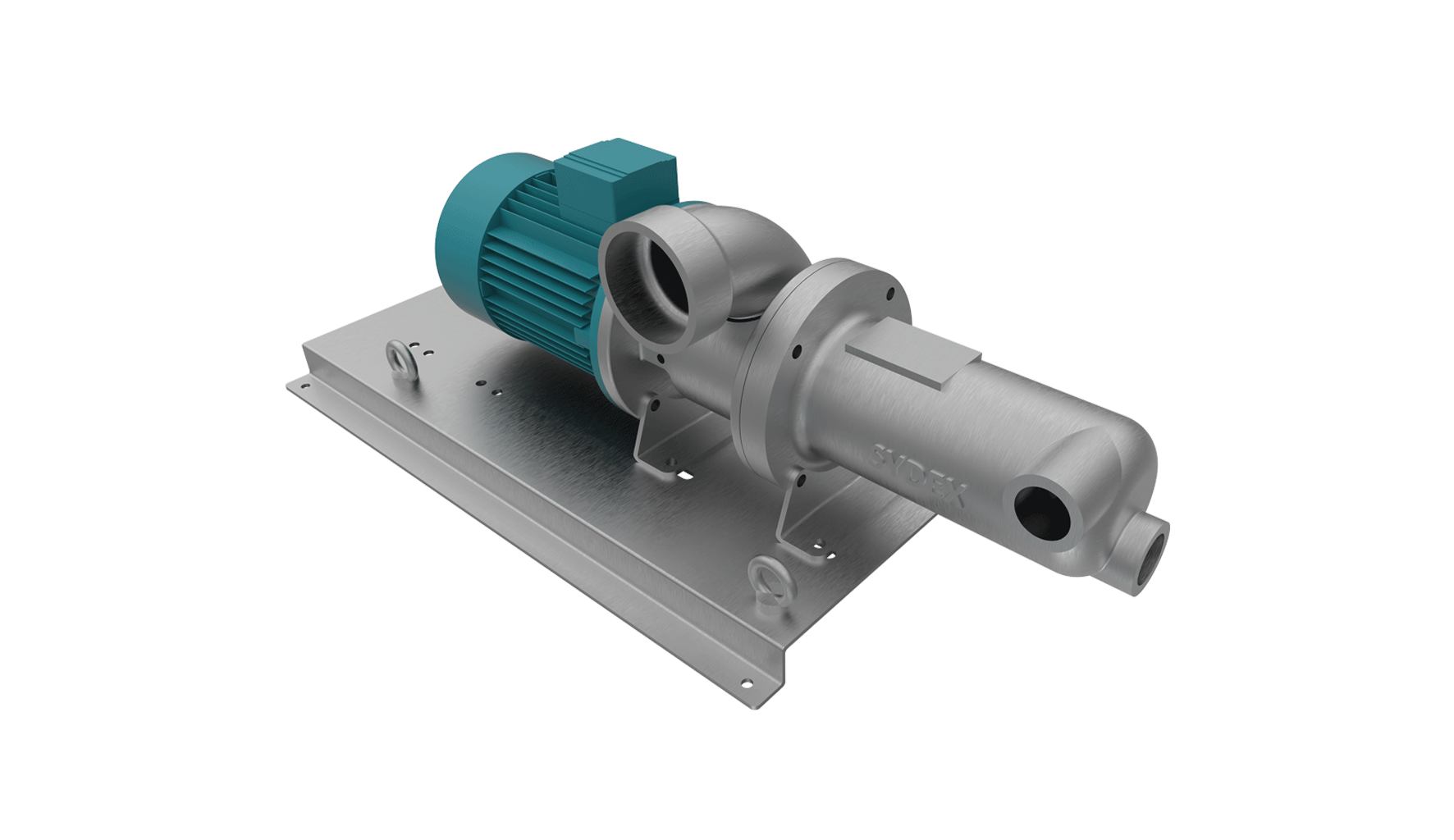

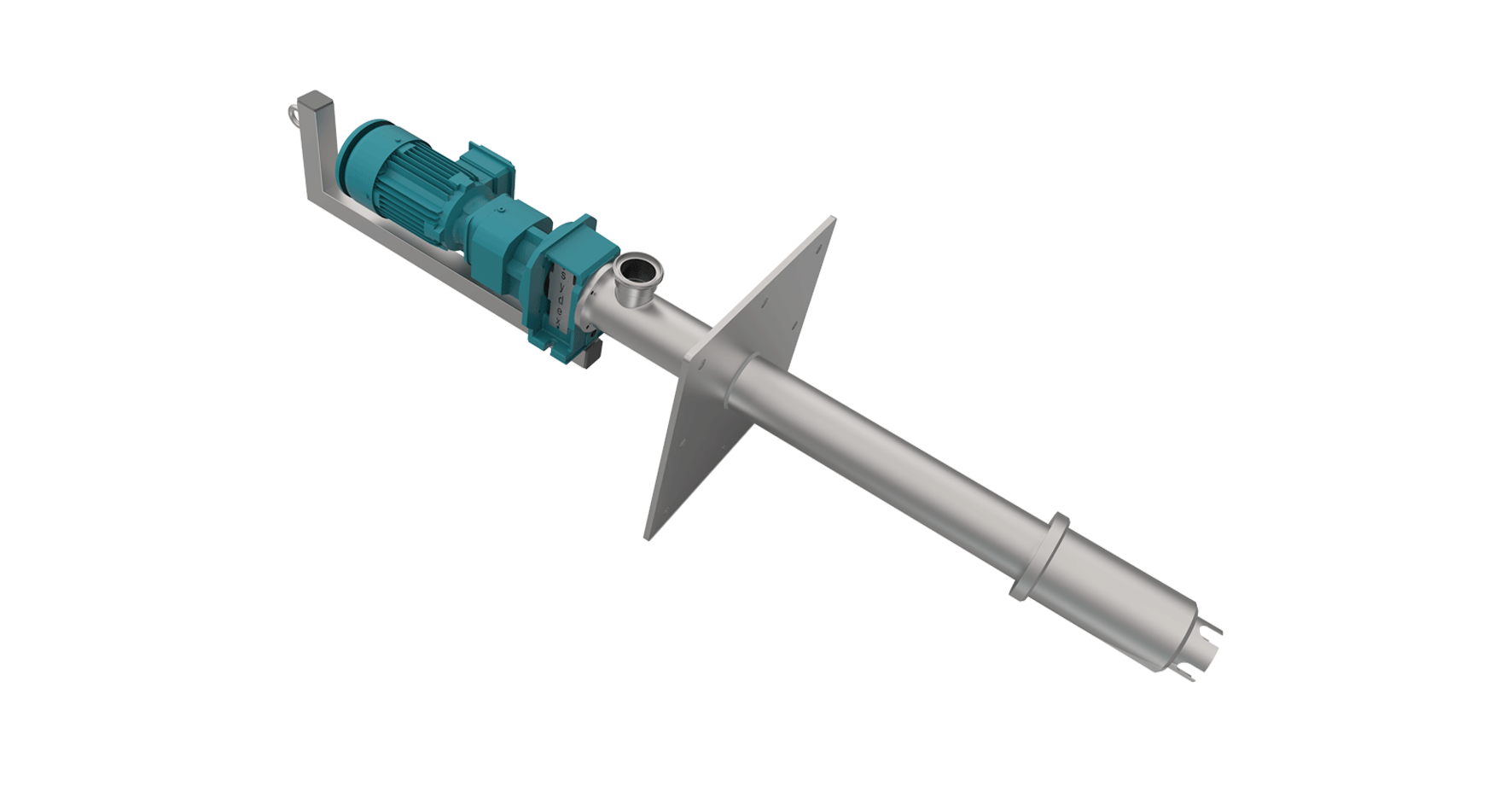

Our products range

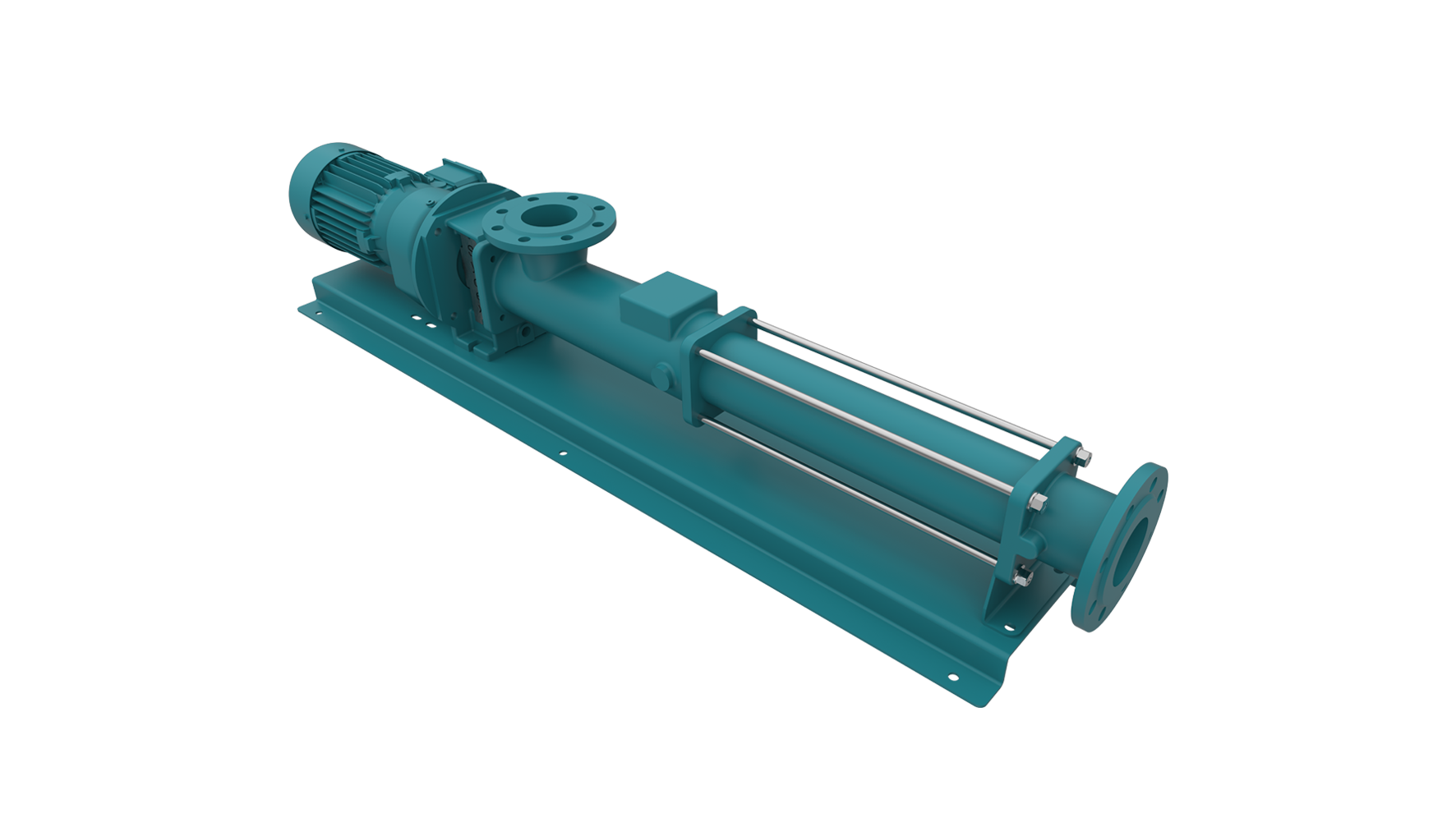

OPERATING PRINCIPLE

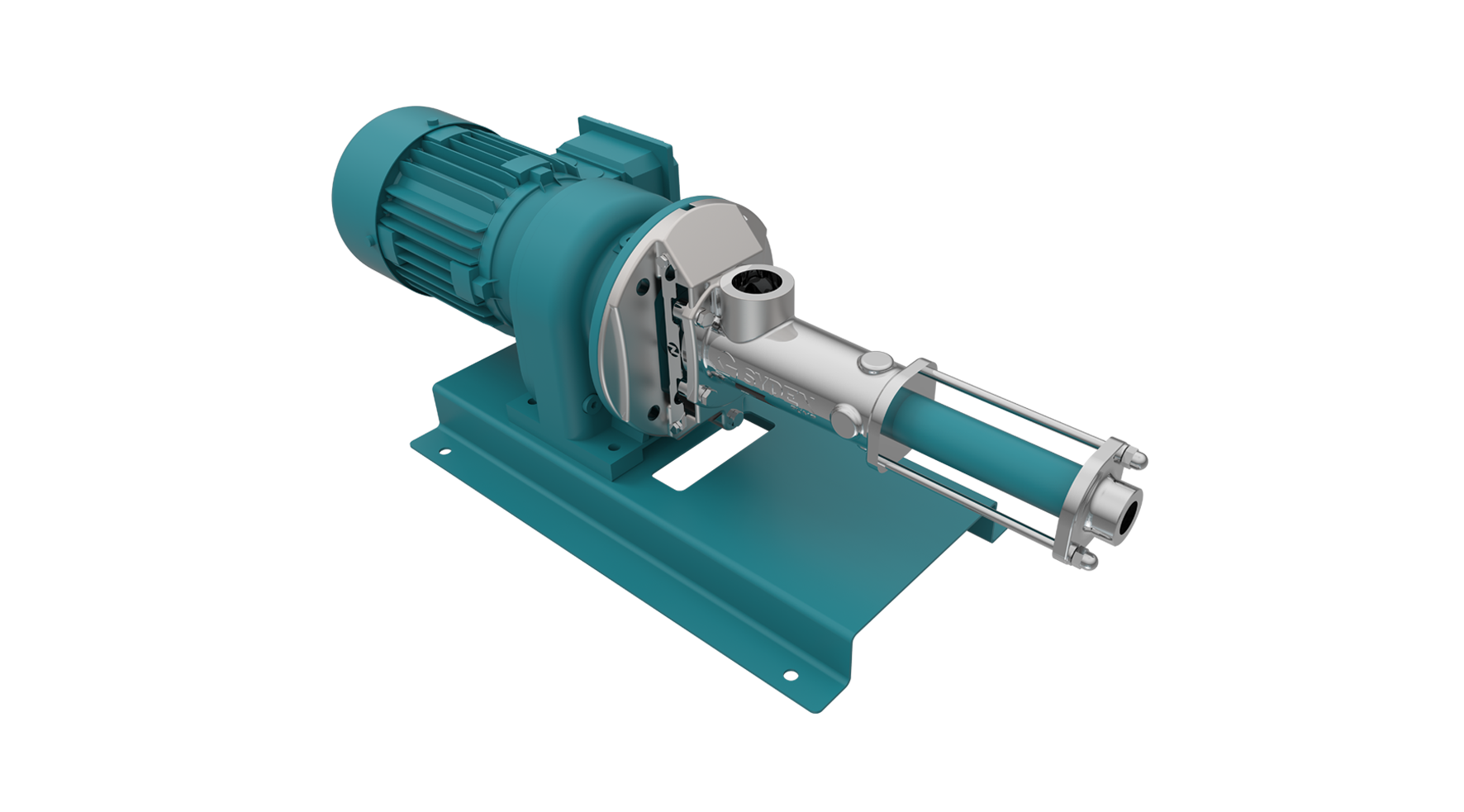

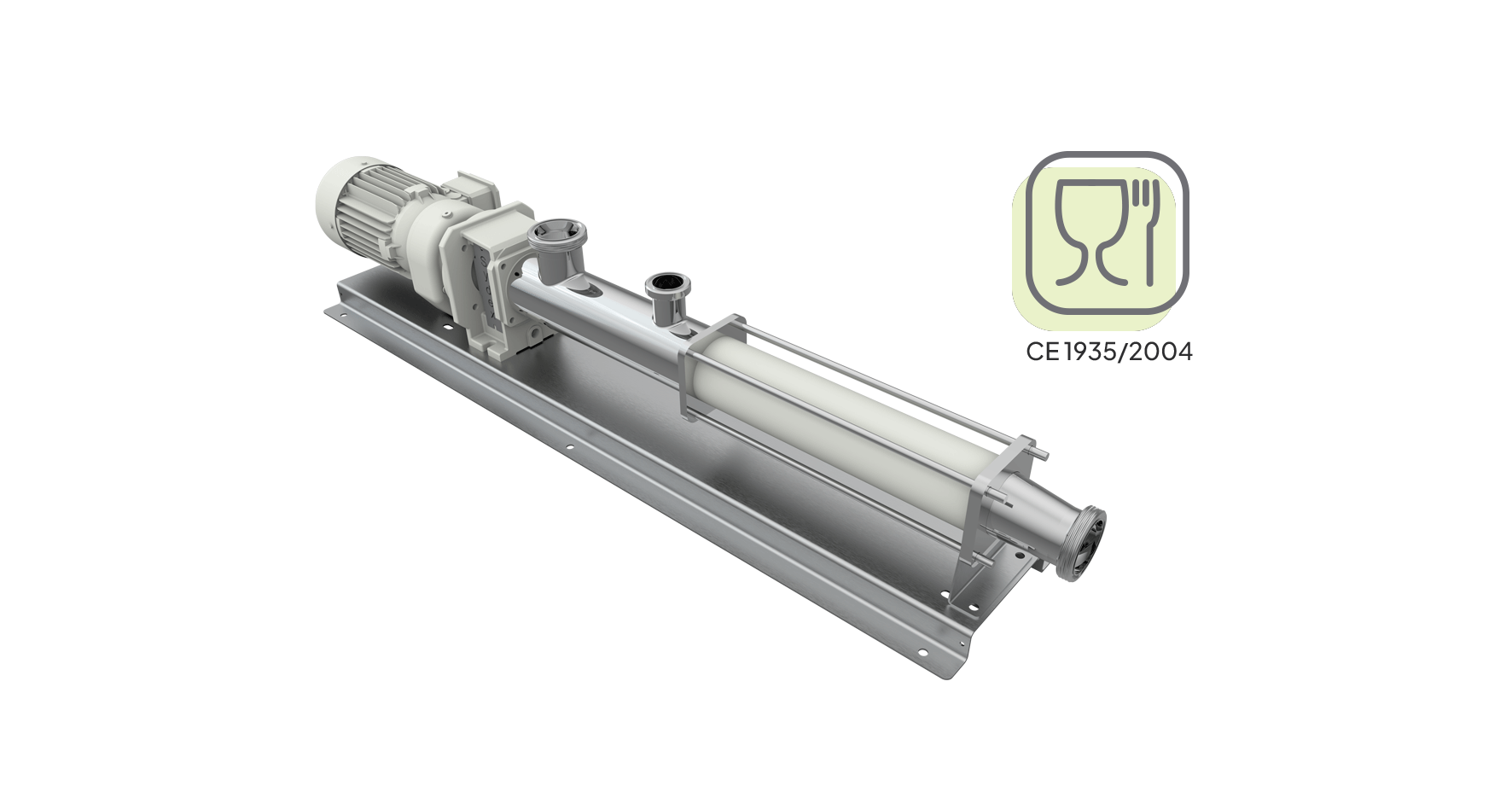

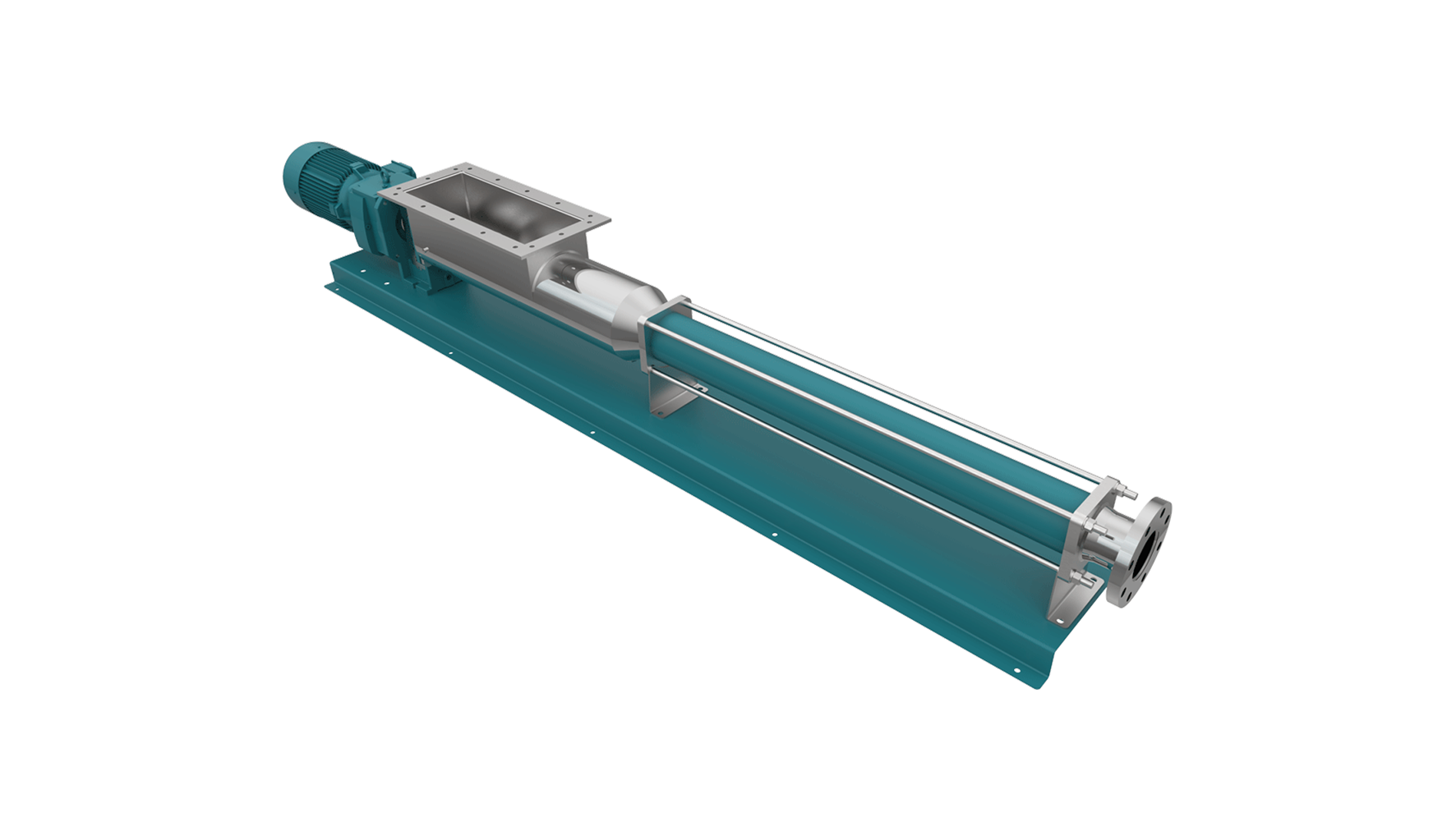

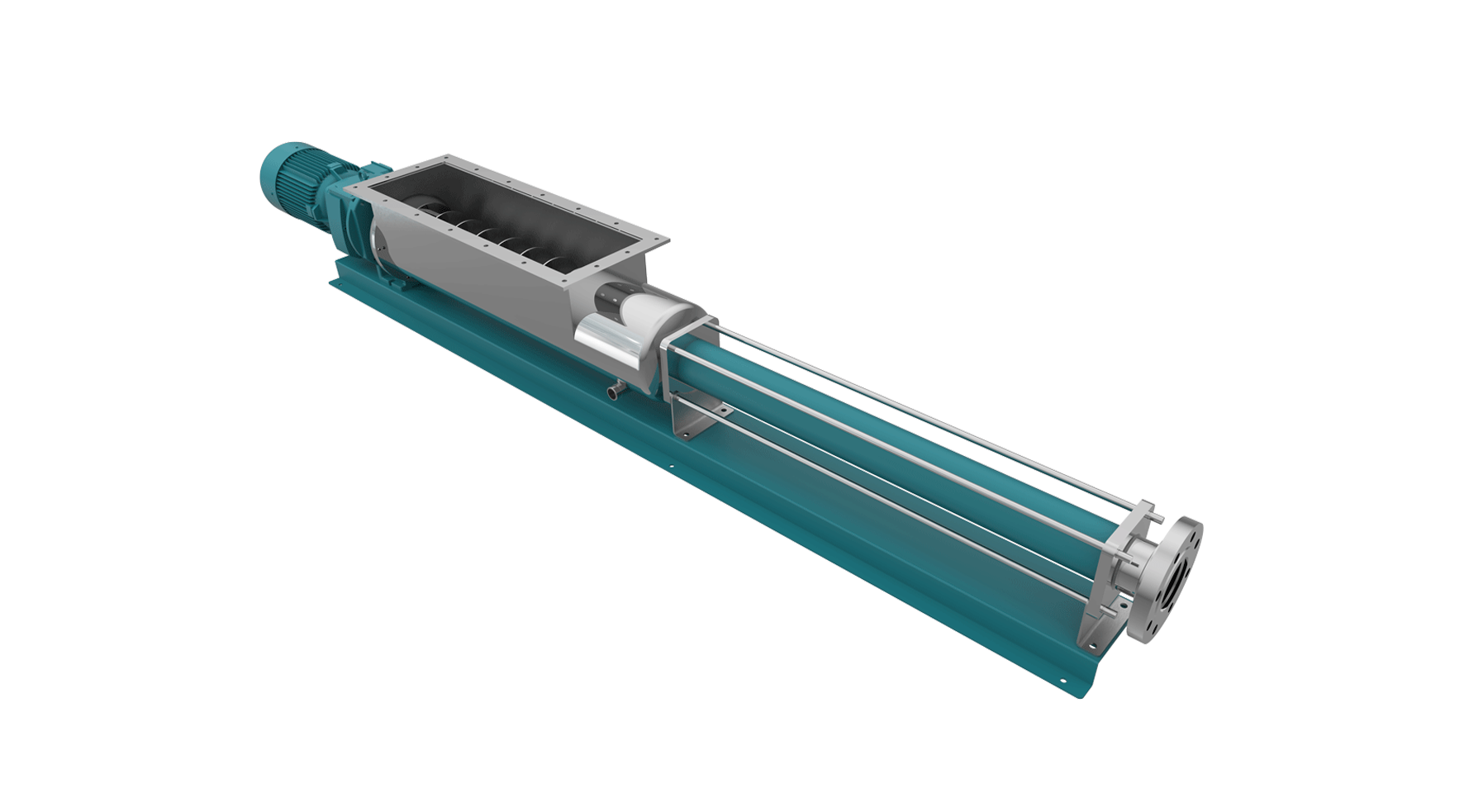

Sydex produces progressing cavity pumps which are part of the positive displacement pumps. The pumping part consists of two elements, the rotor and the stator. The rotor is a screw generally made of metal, which can be single or multi stage. The elastomeric stator has the same eccentricity as the rotor and a pitch lenght twice that of the rotor, thus allowing the creation of airtight delivery chambers between the stator and the rotor. Thanks to the rotary movement of the rotor inside the stator, the chambers are transferred from the suction port to the discharge one without changing shape or volume. In this way the product is transferred with a constant flow and low shear effects.

WHY CHOOSE A PROGESSIVE CAVITY PUMP:

• It transfers high-viscosity products

• It is ideal for handling fragile products because it does not degrade them and it does not alter them during the transfer

• It can transfer not homogeneus products, containing gas and abrasive material, solids and fibrous substances

• It has a high self-priming capacity

• The flow is constant and vibration-free

• The flow can be reversible

• The flow is proportional to the speed

• It can perform dosing tasks

• It requires a low torque even at maximum performance