At the client’s service: Ad-hoc manufacturing

24 July 2024

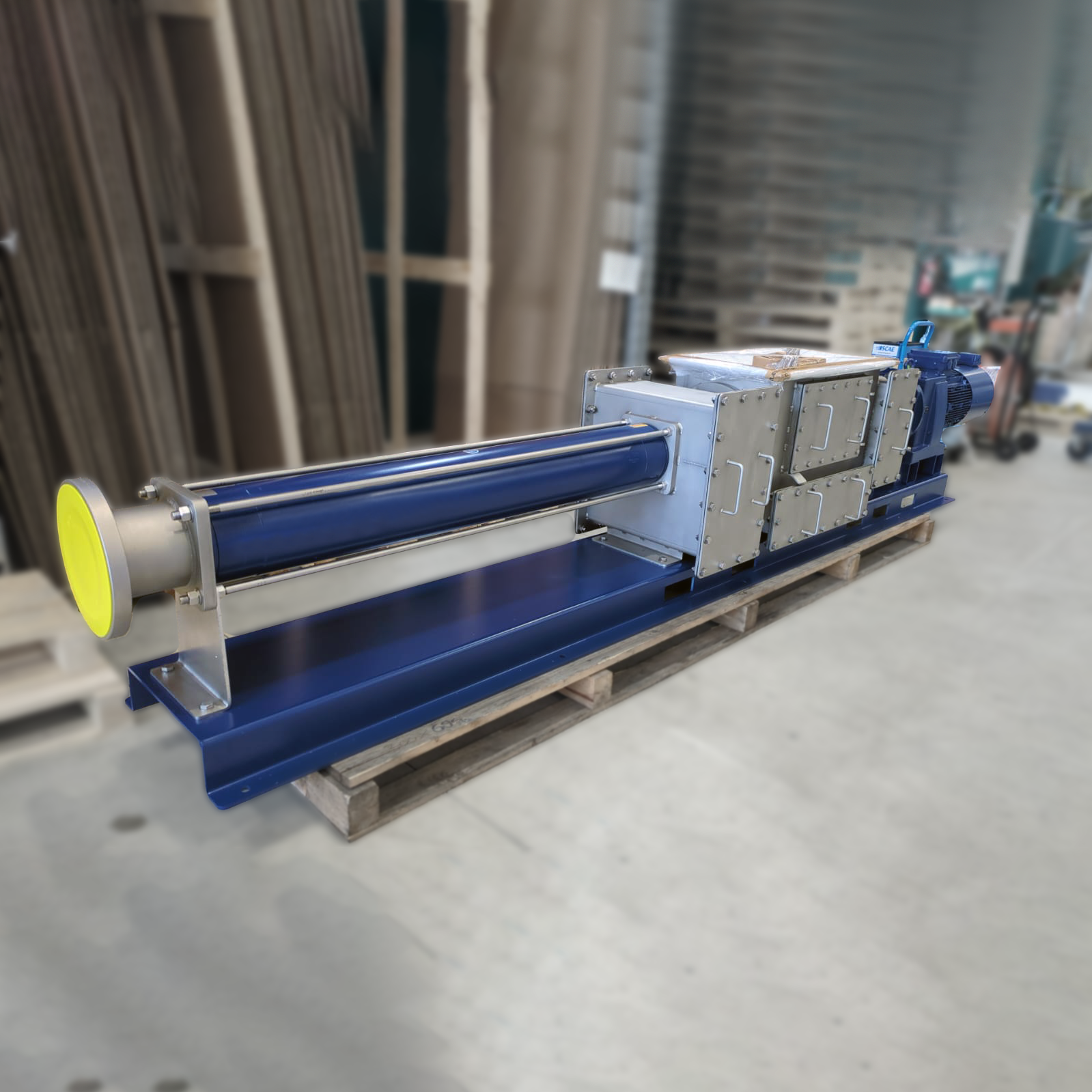

In the waste treatment sector, operational and technical challenges are commonplace. Since the plant in question treats extremely dirty and abrasive dehydrated sludge, with large-sized blunt solids, a custom-made pump that can ensure greater operation was the natural solution to the problem.

By combining control over the customer’s process and the design of the pump, we have created an XXL version of the hopper that can also house doors and drawers to collect stones and foreign bodies that would ruin the stator, preserving it.

Thanks to the combination of excellent hydraulics, finely studied materials and robust mechanical construction, the pump will be able to perform at its best and satisfy the customer’s stringent requests!

Fluid: Dehydrated mud with usual large-sized blunts (20-80cm)

Viscosity: 100000 cPo

Temperature: 35°C

Flow rate: 8 m3/h

Delivery pressure: 12 bar