Applicazioni e mercati

Ci adattiamo ad ogni richiesta

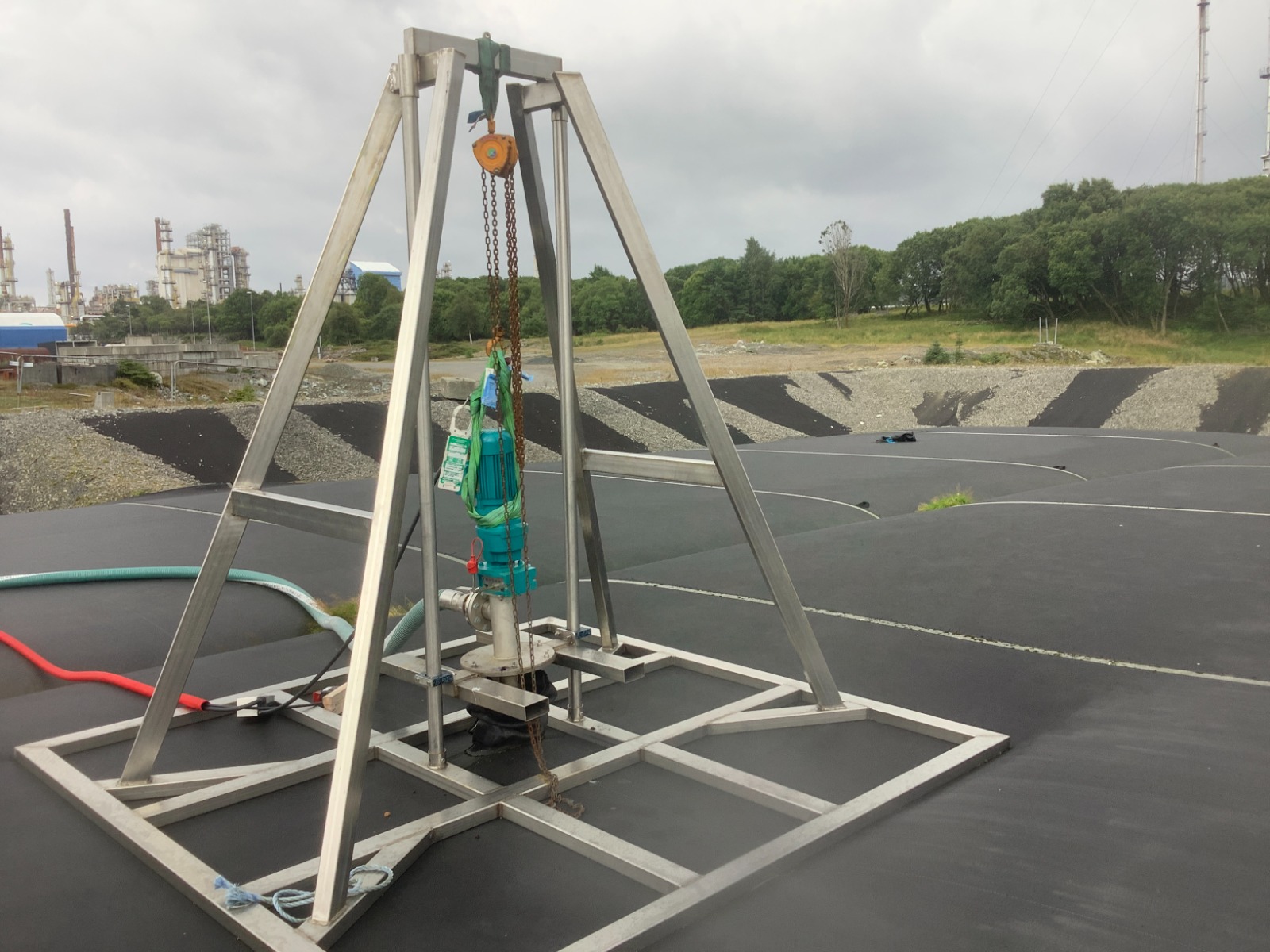

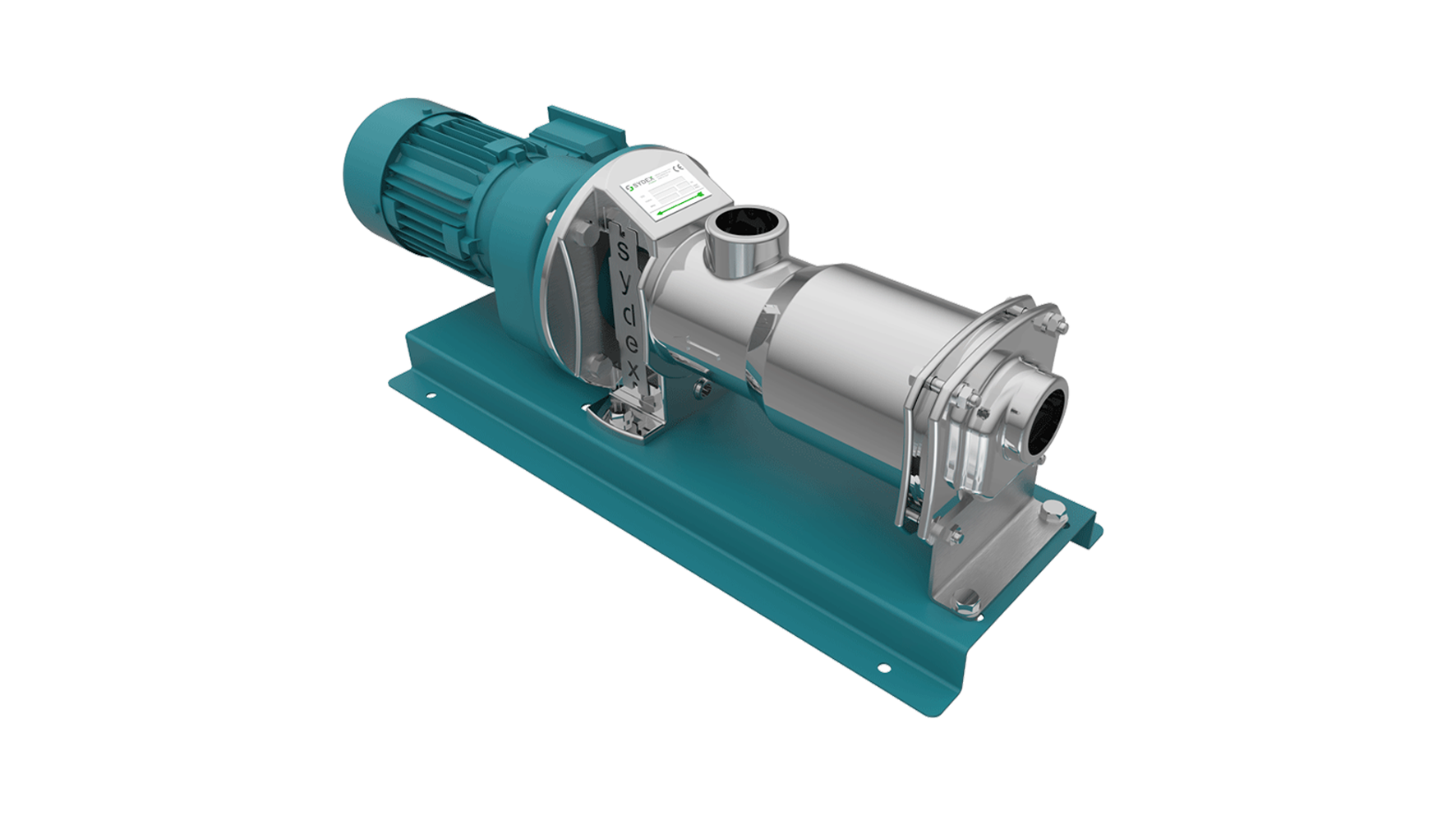

Sydex fornisce un’ampia gamma di pompe volumetriche a cavità progressiva, trituratori e maceratori per soddisfare le esigenze specifiche dei diversi mercati e applicazioni. Grazie alla sua esperienza e alla conoscenza dei mercati, Sydex è in grado di adattare i propri prodotti alle necessità dei clienti scegliendo tra una grande varietà di materiali e componenti.

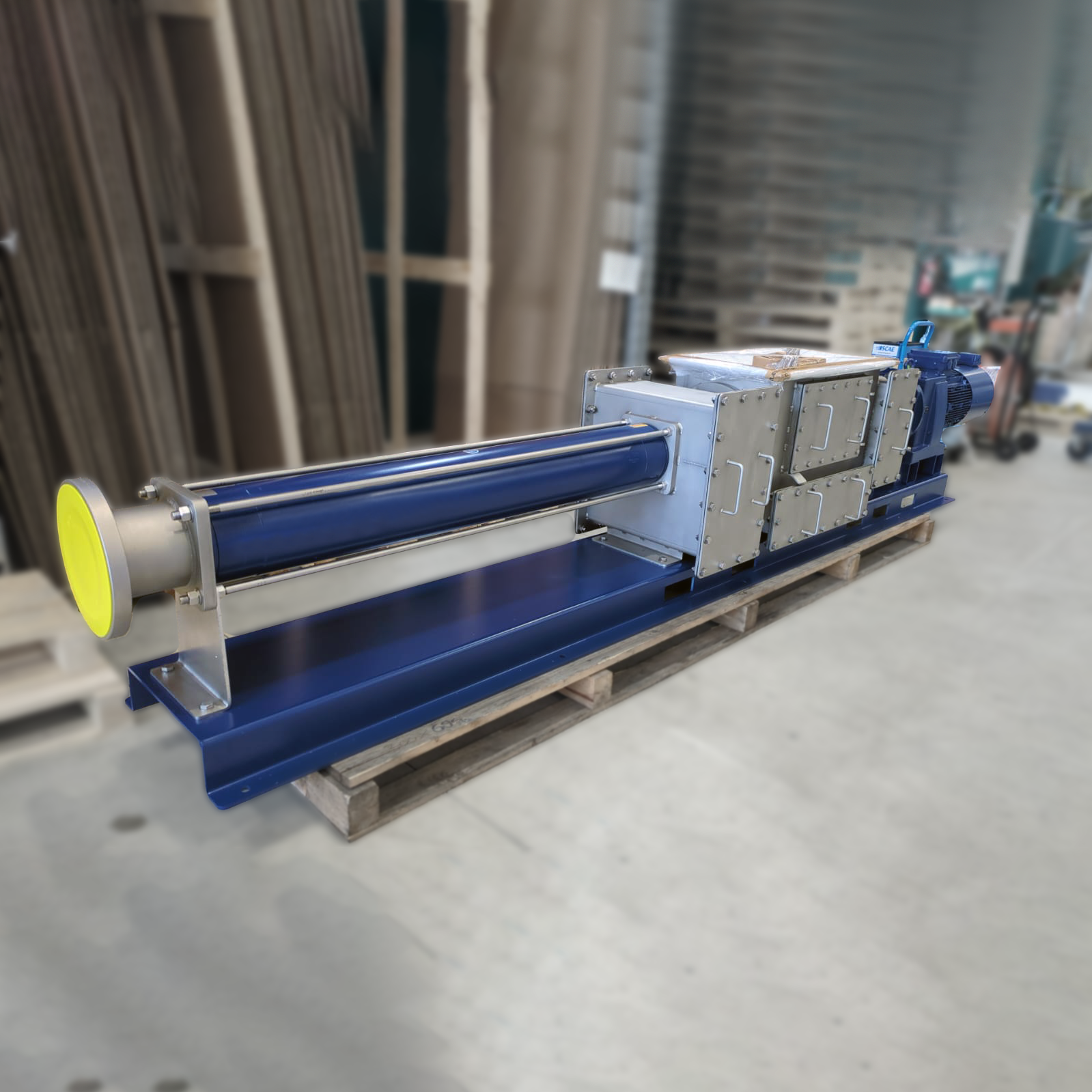

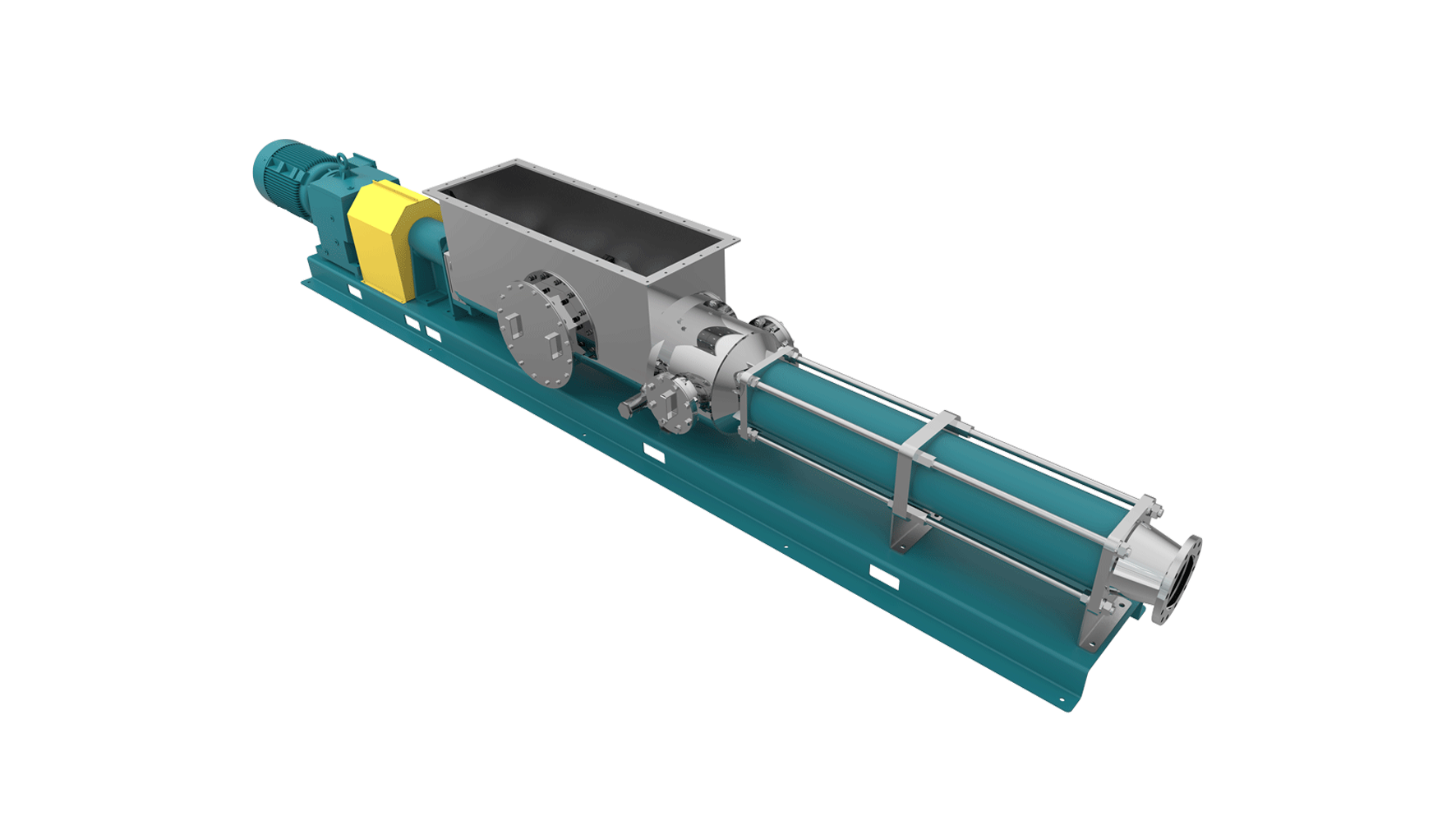

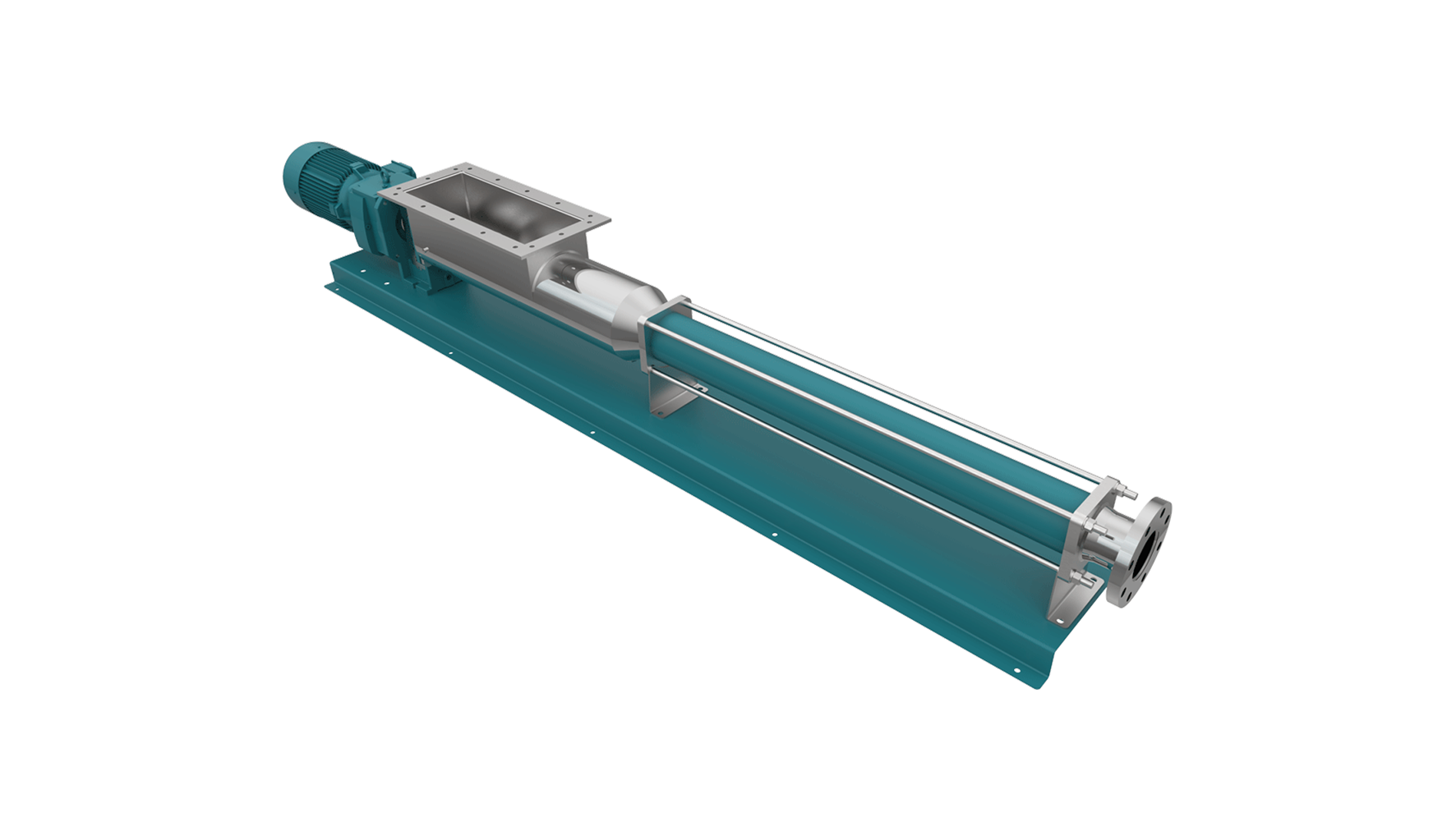

Pompe a cavità progressiva

Sydex è un’azienda italiana dinamica, affidabile ed affermata a livello internazionale che produce e commercializza pompe a cavità progressiva.

La profonda conoscenza del prodotto e delle sue molteplici applicazioni ci hanno permesso di sviluppare una gamma di prodotti adatti alle diverse necessità del cliente. Offriamo un servizio di assistenza attento e puntuale, dallo studio del progetto fino al trasporto e al post-vendita.

20

anni di esperienza

50000

pompe installate

4

filiali in tutto il mondo

I nostri prodotti

Per qualsiasi necessità, abbiamo la soluzione

Sydex produce una vasta gamma di pompe a cavità progressiva, che si adatta alle più diverse necessità di portata, pressione e applicazione: forniamo soluzioni per il dosaggio, con portate di pochi litri/ora fino ad arrivare a modelli con portate di 300 m³/ora.

Anniversario

20 anni di successi!

La storia di Sydex è un racconto di resilienza, innovazione e successo. Fondata vent’anni fa da un team di visionari determinati a trasformare il panorama tecnologico delle pompe, Sydex ha rapidamente conquistato un posto di rilievo nel settore.

Con una determinazione minimalista ma ambiziosa, Sydex ha adottato un approccio basato sull’efficienza economica e la rapidità, ponendo sempre l’accento sulla qualità e l’affidabilità dei propri prodotti. Questo ha portato a risultati straordinari, con oltre 47.000 pompe installate in tutto il mondo.

La chiave del successo di Sydex risiede nella sua capacità di adattarsi alle mutevoli esigenze del mercato, anticipando le tendenze e offrendo soluzioni innovative. La tecnologia all’avanguardia è stata sempre al centro della missione dell’azienda, consentendo di offrire prestazioni superiori e costi ridotti per i clienti.